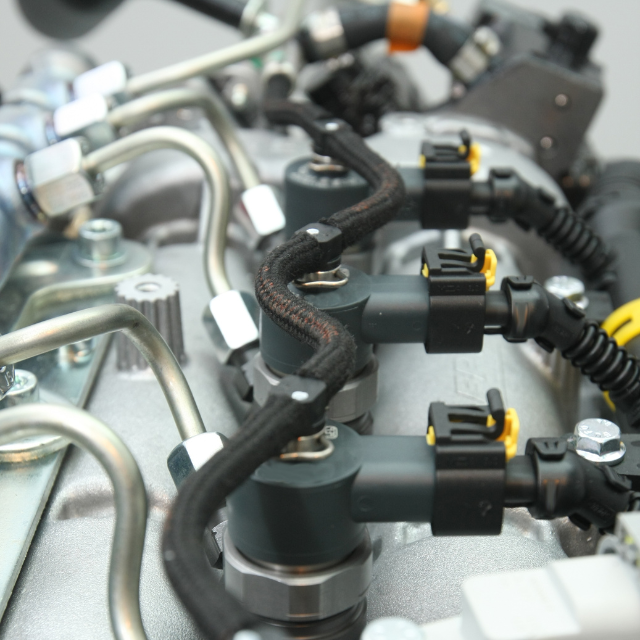

Development of a functional prototype for a direct injection (DI) hydrogen fuel rail for a heavy-duty internal combustion engine.

- Identification of the key requirements derived from the specific application as well as from regulatory constraints

- Definition of a suitable layout and overall design within the available installation space

- Definition of a design concept based on a target volume

- Design and preparation of manufacturing documentation for the fuel rail, injector lines, and feed line

- Participation in D-FMEA and P-FMEA activities to validate and safeguard both the design and the manufacturing process

- Design and preparation of manufacturing documentation for test setups (validation), tools, and fixtures

- Continuous coordination with the OEM, prototype manufacturing, suppliers, and other project stakeholders

- Project documentation aligned with IATF requirements up to initial functional prototypes